Your Cart is Empty

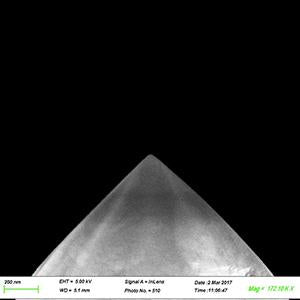

These tips are specifically designed for high mechanical loads and scratch testing applications. By using wear-resistant diamond and a broad cone angle the contact size is well characterized and stays constant during repeated mechanical measurements. These probes have demonstrated highly repeatable deep (~100nm) indentations into materials such as fused silica and can image the indents at high resolution in-situ using the same probe. Each cantilever comes individually characterized with both spring constant and tip radius accurately measured, to enable fully quantitative nanomechanical measurements. Each probe comes with a high-resolution SEM image showing the precise tip shape to enable fully quantitative measurements. A gold reflex coating deposited on the detector side of the cantilever to enhance the reflectance of the laser beam.

Nanomechanical modes: Topography, nanoscratching, and nanoindentation, and their combination with PeakForce QNM, FASTForce Volume, or contact resonance.

| Tip Geometry: | Cone |

| Tip Height: | 12.5 ± 2.5 |

| Tip Radius (Nom): | 10 ± 5 |

| Tip Coating: | Highly conductive single crystal diamond |

| Tilt Compensation: | 1 |

| Back Side Coating: | Reflective Au |